Fertilizer raw material processing machinery and equipment form the core of modern fertilizer production, bridging the gap between raw materials and finished fertilizers. These specialized devices handle a wide range of feedstocks—from organic matter like agricultural waste and livestock manure to inorganic compounds such as urea and phosphate rock—through crushing, mixing, drying, and purification. By optimizing raw material properties, removing impurities, and standardizing component ratios, they lay the foundation for high-quality, nutrient-stable fertilizers, while adapting to diverse production scales and fertilizer types. As the agriculture industry pursues efficiency and sustainability, these machines have become indispensable for upgrading fertilizer production chains.

The processing of organic and inorganic raw materials requires tailored equipment due to their distinct characteristics. For organic raw materials, pre-treatment machinery is critical to address high moisture, complex components, and pathogen contamination. Crushers and shredders reduce bulky materials like crop straw and oil palm empty fruit bunches into fine particles, accelerating subsequent fermentation. Mixers ensure uniform blending of different organic wastes, balancing carbon-nitrogen ratios for efficient decomposition. Drying equipment, such as rotary dryers and belt dryers, lowers moisture content to 20%-30%, preventing mold growth and improving material fluidity for subsequent processing.

Inorganic raw material processing focuses on purification, grinding, and granulation readiness. Phosphate rock crushers and grinders reduce hard ore into fine powder, facilitating acidolysis reactions in compound fertilizer production. Purification equipment removes heavy metals and impurities from raw materials like potassium chloride, ensuring compliance with fertilizer safety standards. For water-soluble fertilizers, dissolvers and filters separate insoluble substances, guaranteeing the clarity and stability of liquid products. These processes not only enhance nutrient availability but also avoid equipment wear caused by hard impurities.

Key machinery categories cover the entire raw material processing workflow, each with unique functions. Crushing equipment, including hammer crushers and jaw crushers, adapts to different hardness levels—jaw crushers for hard inorganic ores and hammer crushers for brittle organic materials. Mixing machinery ranges from horizontal mixers for small-batch production to twin-screw mixers for large-scale, high-precision blending, ensuring consistent nutrient ratios. Drying equipment utilizes thermal energy efficiently: rotary dryers for large-capacity processing and vacuum dryers for heat-sensitive materials, preserving nutrients from degradation.

Advanced technologies are reshaping raw material processing equipment, driving efficiency and sustainability. Intelligent control systems monitor moisture, particle size, and mixing uniformity in real time, enabling automated adjustments and reducing human error. Energy-saving designs, such as heat recovery systems in dryers, lower energy consumption and carbon emissions. Corrosion-resistant materials like stainless steel extend equipment lifespan when handling acidic or alkaline raw materials, reducing maintenance costs for manufacturers.

The importance of these machines extends beyond production efficiency to fertilizer quality and environmental protection. Uniformly processed raw materials ensure stable nutrient content in finished fertilizers, avoiding uneven application that harms crops and soil. For organic raw materials, proper processing eliminates pathogens and odor, reducing environmental pollution from waste disposal. Scalable equipment options—from small-scale crushers for family farms to industrial-grade production lines—support the development of both smallholders and large fertilizer enterprises.

Fertilizer raw material processing machinery and equipment are the unsung heroes of sustainable agriculture. By unlocking the potential of diverse raw materials, optimizing processing workflows, and ensuring product quality, they empower the fertilizer industry to meet the growing demand for eco-friendly, high-efficiency fertilizers, contributing to soil health and food security worldwide.

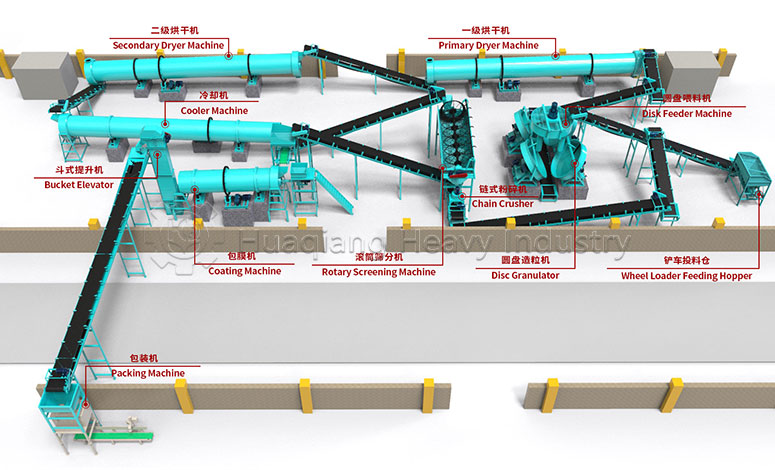

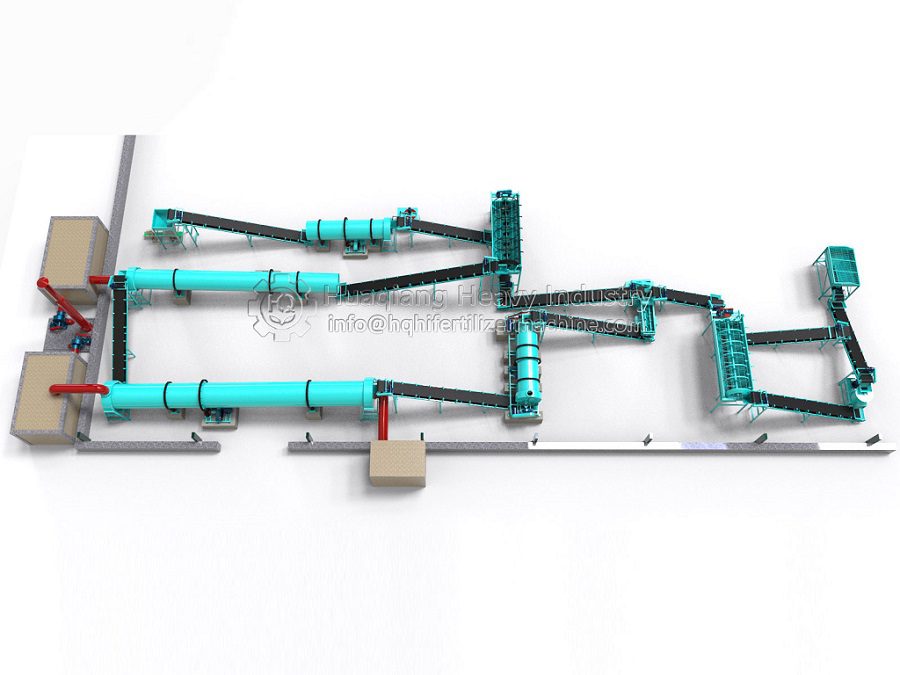

Integrating Processing with Granulation in Fertilizer Lines

The processed raw materials are the essential input for the core npk fertilizer production process and organic fertilizer manufacturing. This processed feedstock—whether inorganic powders or cured organic compost—is channeled into the appropriate production line. In an npk fertilizer line, the materials are first precisely blended using a npk bulk blending machine or a standard npk blending machine to achieve the target nutrient ratio. This entire preparatory stage, executed by sophisticated fertilizer raw material processing machinery and equipment, ensures the consistency required for high-quality granulation.

The granulation stage then shapes the blended material. For NPK production, this often involves a disc granulation production line where a disc granulator (utilizing a disc granulator for shaping) forms spherical granules via wet agglomeration. Alternatively, a double roller press granulator can be used for dry compaction. In an organic fertilizer production line, similar granulation technologies are applied to the processed organic base. The integration of robust processing equipment with these specialized granulators forms the backbone of professional fertilizer manufacturing equipment, creating a seamless flow from raw feedstock to finished, market-ready granules.

Therefore, the efficiency and quality of the final fertilizer product are directly dependent on the synergy between the upstream material processing units and the downstream granulation systems, highlighting the integrated nature of modern fertilizer plant design.