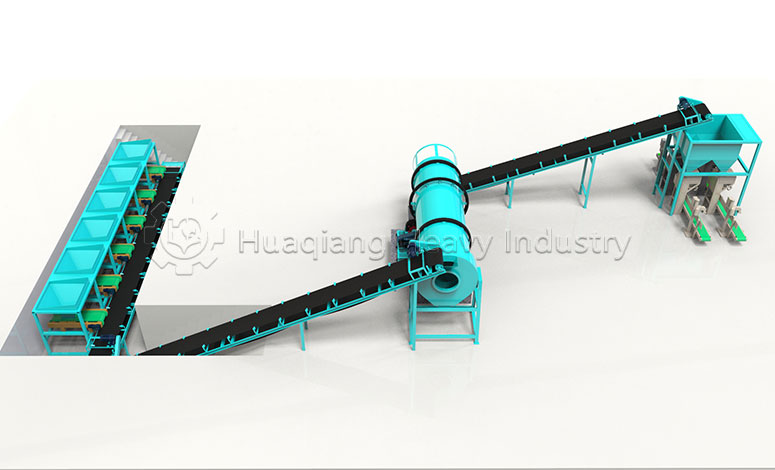

In the modern fertilizer manufacturing field, NPK blending fertilizer production lines, with their precise formulation execution capabilities and flexible production modes, provide strong guarantees for the precise supply of nutrients to crops. This system achieves precise proportions and uniform distribution of various nutrients through the perfect coordination of specialized equipment.

As the core of the entire production line, the NPK blending machine undertakes the crucial mixing task. Its unique structural design ensures that nitrogen, phosphorus, potassium, and various micronutrients reach an ideal mixing state in a short time. This efficient blending process not only guarantees the uniform distribution of nutrients but also ensures that each bag of finished fertilizer has a completely consistent nutrient content.

The fertilizer mixer machine, working closely with the NPK blending machine, plays an important auxiliary role in the mixing process. Through secondary homogenization of the materials, it further improves the homogeneity of the product and eliminates any potential mixing dead zones. The seamless cooperation between the two machines forms the foundation for the quality assurance of the NPK blending fertilizer production line.

The advantage of the entire NPK blending fertilizer production line lies in its outstanding flexibility. Compared to traditional compound fertilizer production lines, it can quickly adjust the formula composition according to different soil characteristics and crop needs, achieving customized production of small batches and multiple varieties. This characteristic allows fertilizer products to better adapt to regional and individualized agronomic requirements.