Producing 3 tons/hour of NPK compound fertilizer granules hinges on achieving “equipment synergy, precise process control, and stable production capacity.” This requires a NPK fertilizer production line matched to this capacity, relying on mature NPK compound fertilizer granulation technology, and controlling parameters at each stage to efficiently produce qualified granules, balancing both yield and quality.

Step 1: Raw Material Pre-treatment and Precise Proportioning. Mix nitrogen, phosphorus, and potassium raw materials and fillers according to the target formula, crush them to 80-100 mesh, and remove impurities; precisely control the proportions through an automatic batching system to ensure uniform nutrient distribution. Then, the mixture is sent to a fertilizer mixer and stirred for 5-8 minutes until evenly mixed, laying the foundation for granulation.

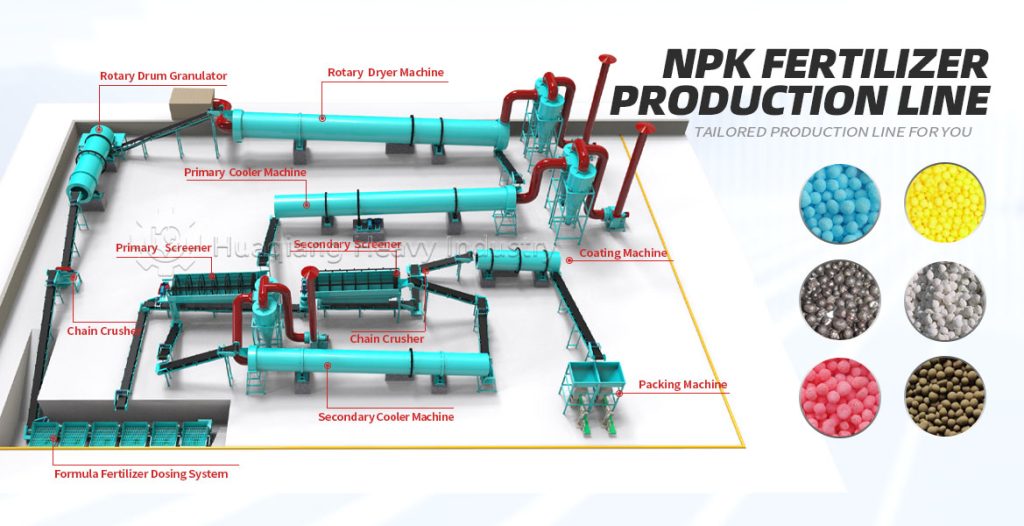

Step 2: Core Granulation Process. Select a rotary drum granulator or double roller press granulator suitable for a 3 tons/hour capacity. Feed the mixed raw materials into the equipment, adjusting the moisture content to 18%-22% and the granulation speed to 20-30 r/min. Utilizing NPK compound fertilizer granulation technology, the raw materials are formed into uniform granules with a particle size of 2-4 mm, ensuring granulation efficiency and granule strength.

Step 3: Drying, Cooling, and Screening. After granulation, the granules are sent to a dryer, controlling the temperature at 80-100℃ to dry them to a moisture content of ≤12%; then cooled to room temperature by a cooler to prevent granule clumping; finally, they are graded by a screening machine, removing unqualified granules, which are returned to the mixer for re-granulation, achieving recycling.

Step 4: Finished Product Testing and Packaging. Test the nutrient content, strength, and other indicators of the granules. After meeting the standards, automatic packaging is performed. The entire production line needs to be coordinated to ensure smooth transitions between each stage, thus achieving a stable 3 tons/hour production capacity. The key is appropriate equipment selection and precise parameter control to efficiently produce high-quality NPK compound fertilizer granules.