In today’s era of accelerating agricultural modernization, the performance of fertilizer machinery directly impacts fertilization efficiency and crop yield. Choosing a high-quality manufacturer is a crucial prerequisite for ensuring stable production and improving overall efficiency. A high-quality fertilizer machinery manufacturer is not only a supplier of equipment but also a long-term partner in agricultural production, and its importance is reflected in every link of the entire production chain.

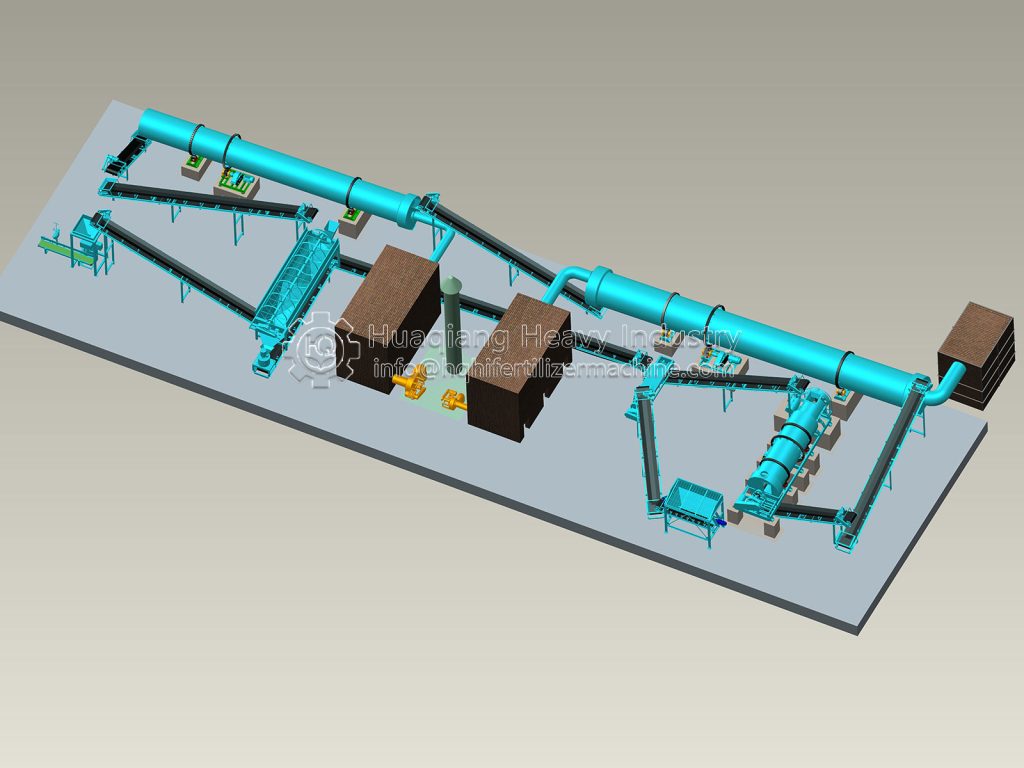

A good manufacturer can guarantee equipment compatibility and production stability. Fertilizer production involves diverse raw materials and varying capacity requirements. A high-quality manufacturer can provide customized fertilizer production line solutions based on the user’s raw material characteristics (such as livestock manure and crop straw) and production scale, avoiding production disruptions caused by mismatched equipment and needs. Data shows that the project delivery success rate of full-process equipment providers is 40% higher than that of single-equipment suppliers, and manufacturers with a high rate of self-manufactured key components have lower equipment failure rates. Conversely, small manufacturers’ assembled equipment often suffers from problems such as drum deformation and inflated capacity claims, seriously affecting production progress.

The technical and service capabilities of a high-quality manufacturer can significantly reduce long-term costs. They have years of experience in the industry and possess accumulated expertise in process optimization and energy-saving technologies, which can reduce overall equipment energy consumption by more than 30%, saving hundreds of thousands of yuan in electricity costs annually. At the same time, comprehensive integrated services can shorten the trial production period, and a 24-hour technical support and spare parts supply system can prevent long-term downtime losses due to equipment failures. Small manufacturers with inadequate after-sales service often leave users in a predicament of “being able to afford the equipment but not being able to use it.”

Choosing a reliable manufacturer is also a guarantee of compliance and market competitiveness. With increasingly stringent environmental regulations, high-quality manufacturers’ equipment can meet exhaust gas and waste residue emission standards, helping users avoid compliance risks. Their mature technology can also improve fertilizer quality, helping products meet industry standards and enhance market recognition.

In summary, choosing a good fertilizer machinery manufacturer is essentially choosing stable production guarantees and long-term development momentum. In the wave of green transformation in agriculture, only by relying on the technology and services of high-quality manufacturers can we achieve cost reduction and efficiency improvement, and build a solid foundation for modern agricultural production.