Production Process Overview

Fertilizer production follows the universal logic of “raw material pretreatment → nutrient synthesis/mixing → granulation and forming → post-treatment → finished product packaging.” Although significant differences exist in specific processes for different fertilizer types, all aim to transform basic raw materials into effective nutrient forms suitable for agricultural use. Modern fertilizer production not only focuses on product efficacy but also emphasizes resource utilization efficiency and environmental protection.

From single-nutrient straight fertilizers to multi-nutrient compound fertilizers, and further to environmentally friendly organic fertilizers, each fertilizer’s production process reflects specific technological routes and engineering wisdom, collectively supporting the global agricultural production system.

Straight Fertilizer Production Processes

Urea Production – Ammonia Stripping Method

Urea, as an important nitrogen fertilizer with up to 46% nitrogen content, is primarily produced using the ammonia stripping method. This process begins with liquid ammonia preparation from natural gas or coal, followed by reaction between liquid ammonia and carbon dioxide in high-pressure reaction towers to form ammonium carbamate, ultimately dehydrated into urea. Reaction products undergo precise decomposition and recovery systems to separate unreacted raw materials, with molten urea forming uniform particles through granulation towers.

Potassium Chloride Production – Flotation Process

Potassium chloride production starts with potash ore mining, using flotation separation technology to effectively separate potassium chloride from impurities like sodium chloride. In flotation machines, special collectors cause potassium chloride particles to attach to rising bubbles while impurities settle, achieving efficient purification. The final product undergoes dehydration and drying, with optional further granulation processing.

Monoammonium Phosphate Production – Acid-Rock Reaction

Monoammonium phosphate production uses phosphate rock and sulfuric acid as raw materials, generating phosphoric acid through acid decomposition reactions, which then neutralizes with liquid ammonia to form MAP slurry. The entire process strictly controls reaction conditions to ensure product purity and nutrient content. The slurry undergoes evaporation concentration and drying granulation to obtain products meeting agricultural requirements.

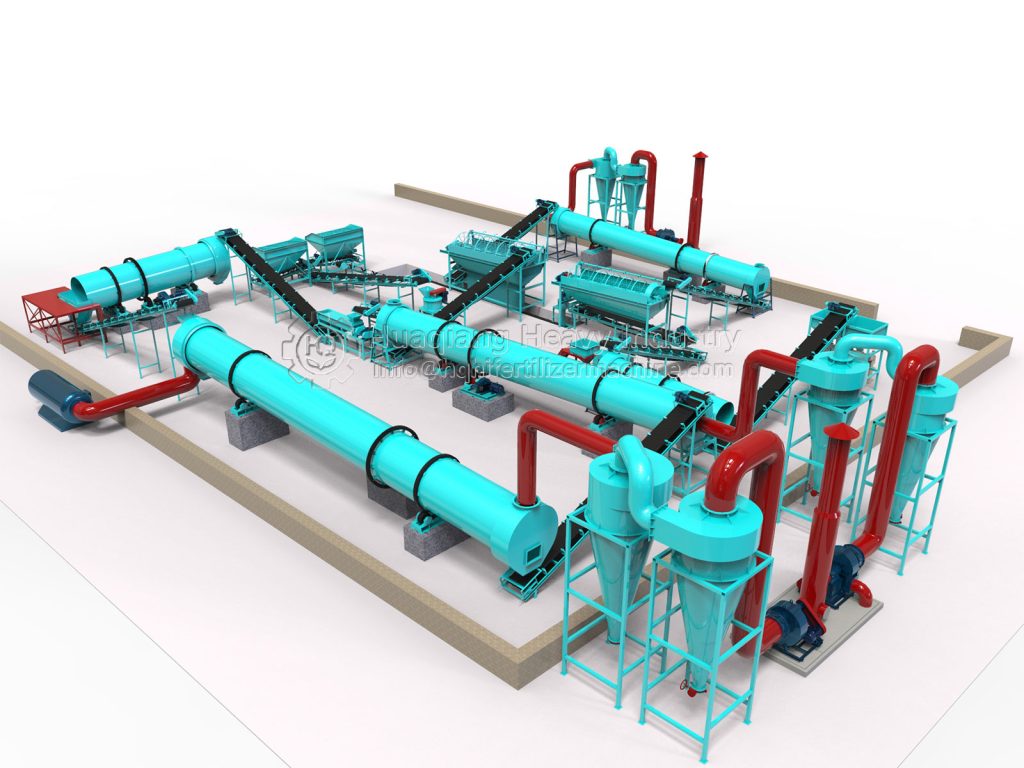

NPK Compound Fertilizer Production Process

Compound fertilizer production involves precise mixing of different straight fertilizers according to specific formulation ratios, achieving large-scale production through drum granulation technology. This process begins with fine pretreatment of raw materials, where all powdered materials must meet specified fineness standards to ensure subsequent granulation uniformity.

Batching Mixing and Granulation

Electronic belt scales precisely measure various raw materials according to preset formulations, thoroughly mixing them in horizontal mixers. The mixed materials then enter drum granulators, where through drum rotation and binder action, uniform 2-4 millimeter particles gradually form via a “snowballing” mechanism.

Drying Screening and Return Material Circulation

Wet particles undergo drum dryers to remove excess moisture, then pass through cooling systems to reduce temperature. Grading screens separate products into qualified particles, overly fine powder, and oversized particles, with the latter two returning to the granulation system as return materials, forming an efficient closed-loop circulation with raw material utilization rates exceeding 95%.

Organic Fertilizer Production Process

Organic fertilizer production centers on environmental protection and resource recycling concepts, transforming agricultural waste into valuable fertilizer products. The production process focuses on achieving raw material harmless treatment and maturation conversion through aerobic fermentation.

Fermentation and Maturation Process

After pretreatment, raw materials undergo aerobic fermentation with the action of fermentation agents. Regular turning or forced aeration maintains suitable temperature and oxygen conditions, continuing for 15-30 days at 55-65°C high temperatures, effectively eliminating pathogens and insect eggs while promoting organic matter decomposition and conversion.

Finished Product Processing

Matured materials undergo crushing and screening to remove undecomposed impurities, with optional addition of appropriate inorganic nutrients to create organic-inorganic compound fertilizers. Finally, through granulation, drying, and packaging processes, commercial organic fertilizer products are formed.

Quality Control and Environmental Requirements

Modern fertilizer production places high importance on product quality control and environmental protection. Precise batching systems and process monitoring ensure nutrient content compliance, while strict granulation parameter control guarantees particle physical performance. Meanwhile, advanced exhaust gas treatment, wastewater recycling, and solid waste comprehensive utilization technologies minimize environmental impacts from production processes.

From specialized synthesis of straight fertilizers to precise formulations of compound fertilizers, and further to biological conversion of organic fertilizers, continuous innovation in fertilizer production processes provides solid guarantees for global food security and agricultural sustainable development.

Modern Fertilizer Manufacturing: Integrating Diverse Production Lines

The evolution of professional fertilizer manufacturing equipment has revolutionized agricultural nutrient production across all fertilizer types. Modern fertilizer granulation processes employ specialized machinery tailored to different product requirements. For compound fertilizers, the npk fertilizer production line integrates npk blending machines with advanced granulators like the disc granulator or double roller press granulator, forming the core of disc granulation production line operations. These fertilizer granulator systems ensure precise nutrient formulation and consistent particle quality.

Organic fertilizer production utilizes specialized systems such as the bio organic fertilizer production line, where windrow composting machines facilitate efficient decomposition before granulation. The complete organic fertilizer production line and npk fertilizer line both demonstrate how modern roller press granulator production line technology and disc granulator machines transform raw materials into uniform, market-ready products. These integrated systems represent the pinnacle of professional fertilizer manufacturing equipment, supporting sustainable agriculture through efficient, environmentally-conscious production methods that meet diverse crop nutrient requirements while maximizing resource utilization.