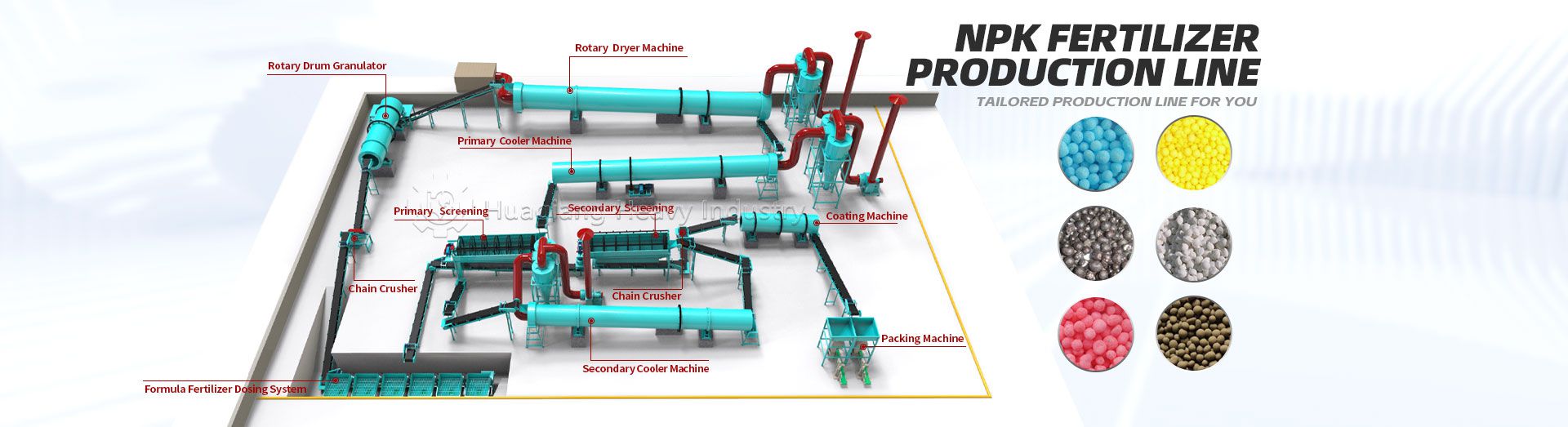

In the granulation stage of organic fertilizer production lines, rotary drum granulators are the preferred equipment for most companies due to their high adaptability to the characteristics of organic fertilizers. Their unique operating principle and performance advantages effectively address key challenges in the granulation process, ensuring product quality and production efficiency.

In terms of granulation adaptability, rotary drum granulators perfectly match the characteristics of organic fertilizer raw materials. Organic fertilizer raw materials, mostly livestock and poultry manure and composted straw, have complex compositions and contain a large amount of fiber. The rotary drum granulator uses the centrifugal force, extrusion force, and friction generated by the rotating drum to granulate loose raw materials without excessive compression, thus preventing the destruction of organic matter and functional microbial activity in the raw materials due to strong compression. The rotary drum granulator also adapts to fluctuations in raw material moisture content (it can handle raw materials with a moisture content of 25%-40%), reducing the tedious pre-treatment process.

The advantages in granulation efficiency and finished product quality are significant. The drum length and diameter of the rotary drum granulator can be flexibly designed to meet production capacity requirements. A single unit can achieve an output of 1-20 tons/hour, meeting the needs of production lines of varying sizes. Its granulation process is gentle and uniform, resulting in highly rounded granules (over 90% roundness). The particle size can be controlled between 2-5mm by adjusting the drum speed and the baffle, meeting standard requirements for organic fertilizer granules. The granules also possess moderate strength, preventing breakage during transportation while slowly disintegrating in the soil, enhancing nutrient release efficiency.

From a cost and environmental perspective, the rotary drum granulator is also competitive. Its simple structure, minimal transmission components, and low failure rate mean ongoing maintenance costs are approximately 30% lower than those of other granulation equipment (such as disc granulators and extrusion granulators). Furthermore, the granulation process does not require the addition of large amounts of binders; granulation is achieved solely through the raw material’s inherent viscosity. This reduces raw material costs while preventing the impact of foreign matter on the purity of the organic fertilizer, aligning with green production principles.

The comprehensive advantages of the rotary drum granulator in adaptability, efficiency, cost and environmental protection make it an ideal choice for the granulation link of the organic fertilizer production line, providing strong support for enterprises to achieve high-quality and high-efficiency production.