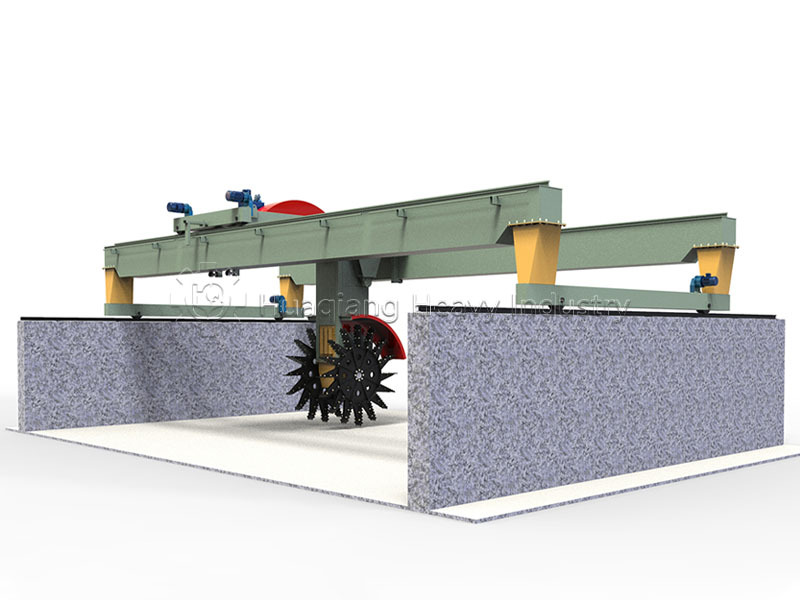

The disc granulator, a core component of the organic fertilizer production line, acts as a “shaping craftsman.” Every step directly impacts pellet quality and safe and stable production. To maximize the performance of this critical piece of equipment, a rigorous and organized standard operating procedure is essential.

The 10 minutes before startup are essential. First, inspect the equipment: check for cracks or loosening on the disc liner, ensure adequate lubrication of transmission components (oil level should be 1/2-2/3 of the mark), and tighten the anchor bolts to prevent loosening. Prepare the raw materials: control the moisture content to 25%-35% (if too high, air dry; if too low, add water). Screen out impurities larger than 5mm to prevent clogging. Finally, perform a safety inspection, clear surrounding debris, securely close the guardrails, test the emergency stop button and overload device, and ensure proper functioning of the electrical circuits and instruments.

The 5-minute startup operation must be performed in a sequential manner. First, start auxiliary equipment such as the raw material conveyor and humidifier. Once these equipment stabilizes, start the granulator’s main motor to avoid damage caused by load. Adjust the disc inclination angle according to the material (lower for clay, higher for organic matter, 45°-55°). Set the speed to 15-20 r/min. Once the disc granulator stabilizes, slowly open the feed valve. Initially, feed at 60% of the rated capacity.

Continuous monitoring is required during operation. Check pellet formation every 10 minutes. Acceptable particle size is 2-5mm. If the pellets are too fine, reduce the feed rate or increase the inclination angle. If there is sticking, reduce the water content. Record parameters every 30 minutes. If the motor current is ≤ 90% of the rated value and the bearing temperature is ≤ 65°C, immediately shut down the machine for investigation.

The minimum shutdown time is 15 minutes. First, close the feed valve, drain the material, turn off the humidifier and main motor, clean any remaining material, inspect components for wear, and keep a maintenance log.

During the entire disc granulator operation, operators must strictly adhere to safety procedures at all times, wear dust masks and hard hats, and never open the guardrail while the machine is running. Only by implementing standardized procedures at every stage can safe and efficient organic fertilizer production be truly achieved.