The core difference between organic fertilizer production equipment and bio-organic fertilizer equipment stems from different process objectives: the former focuses on the harmless and resourceful transformation of organic waste, while the latter requires additional assurance of the activity of beneficial microorganisms. This directly determines the differences in equipment configuration and process control, adapting to different production needs.

Organic fertilizer equipment processes raw materials such as livestock manure and crop straw, achieving harmless degradation through fermentation and granulation. The core objective is to remove pathogens and insect eggs and transform organic matter to produce ordinary organic fertilizer. Bio-organic fertilizer equipment, on the other hand, adds functional microbial agents to this process, ensuring the activity of the microbial agents throughout the process. The core objective is to balance composting and the preservation of live bacteria.

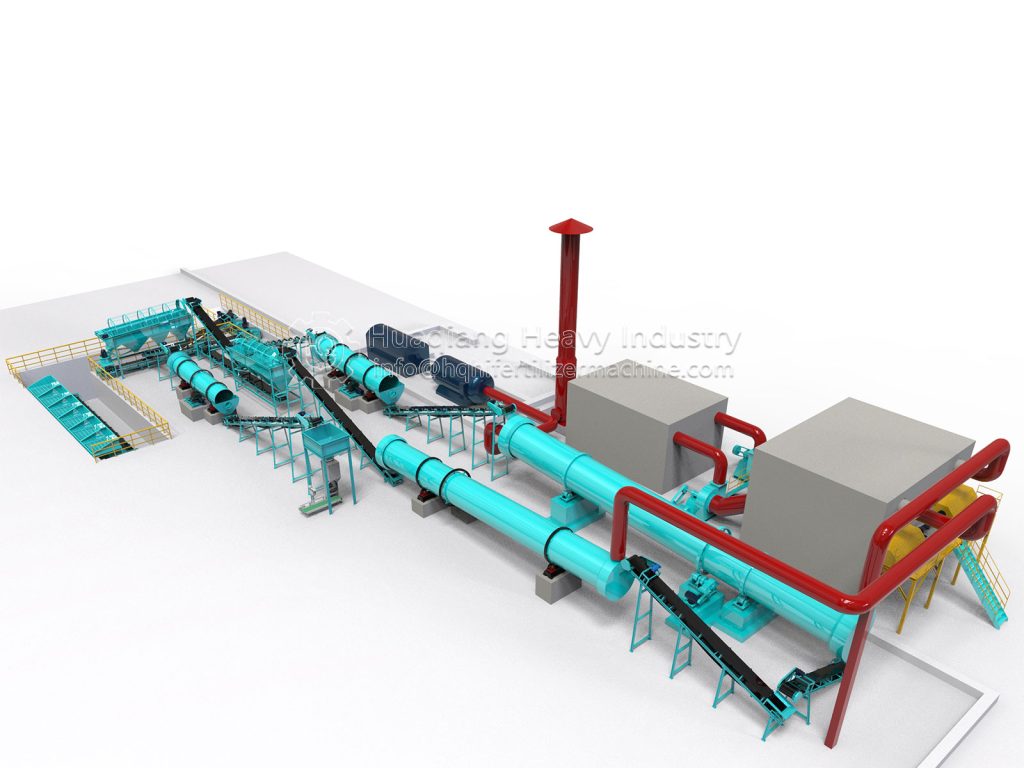

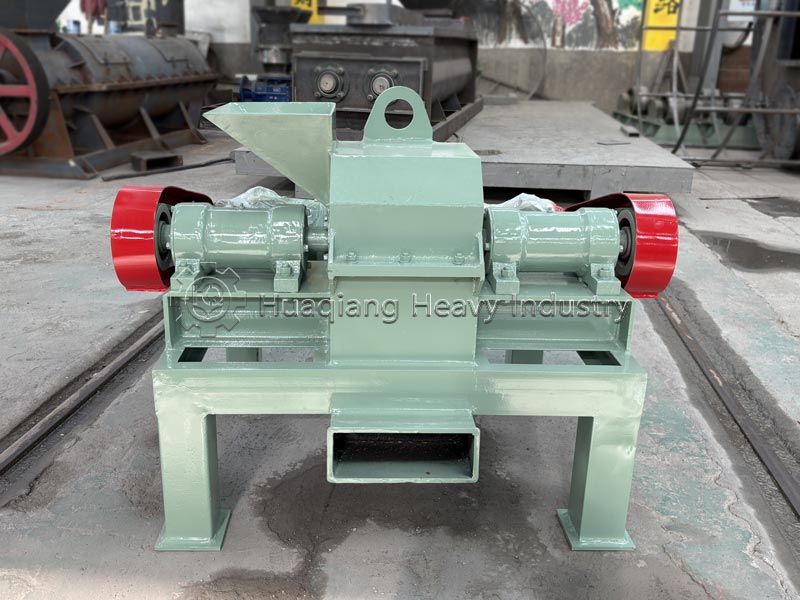

There are differences in key equipment configuration. Both types of equipment share basic equipment such as solid-liquid separators, fertilizer mixers, and granulators, but bio-organic fertilizer equipment requires additional specialized devices: low-temperature fermentation equipment to prevent high-temperature sterilization, precise microbial agent mixing equipment to ensure even distribution, and low-temperature drying/cooling equipment below 60℃ to preserve microbial activity.

Bio-organic fertilizer equipment requires strict control of fermentation temperature, pH value, and the timing of microbial agent addition; ordinary organic fertilizer equipment has a simpler process, focusing on controlling the degree of raw material decomposition. In terms of application scenarios, the former is suitable for ecological farming, while the latter meets the needs of ordinary organic fertilizer production for conventional soil improvement and fertilization.