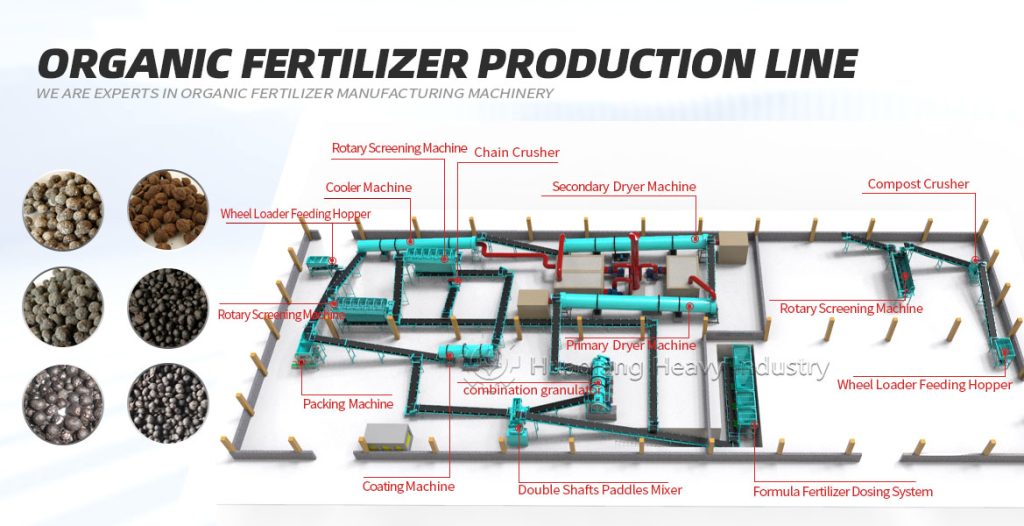

Organic fertilizer production utilizes a wide range of raw materials, with livestock and poultry manure, agricultural crop residues, and industrial organic byproducts being the three most commonly used types. Each type has a different nutrient structure, and after scientific processing with organic fertilizer production equipment, they can be transformed into high-quality organic fertilizers.

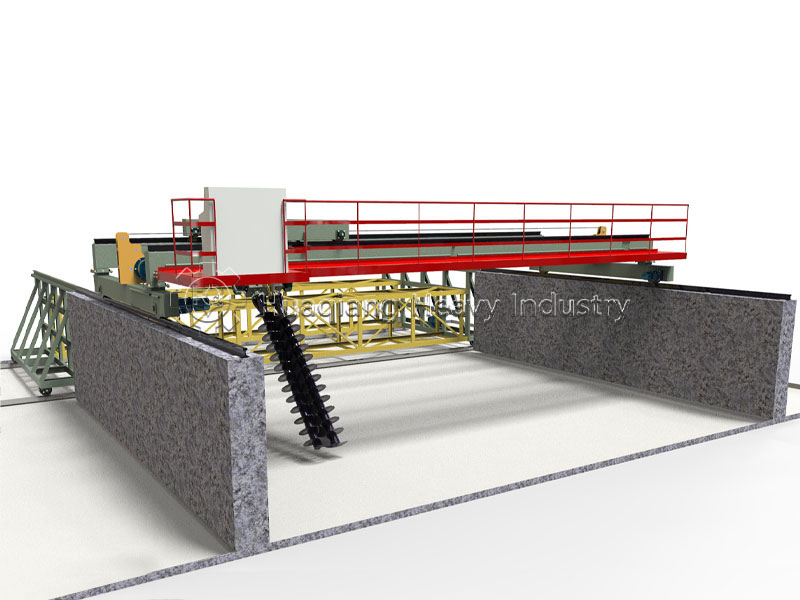

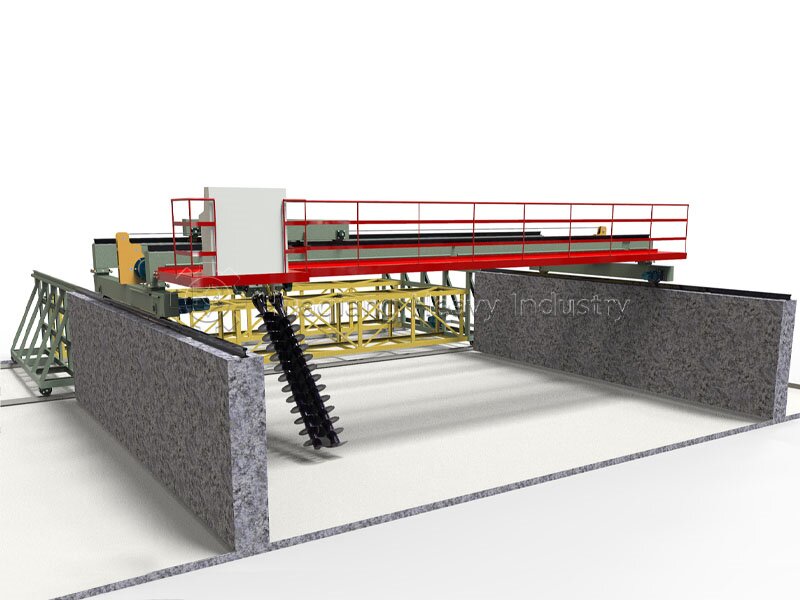

Livestock and poultry manure is rich in nutrients, including chicken manure, pig manure, and cow manure, and is abundant in nitrogen, phosphorus, potassium, organic matter, and amino acids, providing a gentle and long-lasting fertilizing effect. Fresh manure cannot be used directly; it needs to undergo high-temperature fermentation and composting through an organic fertilizer production line to kill insect eggs, pathogens, and weed seeds, reduce salt content, and prevent seedling burn.

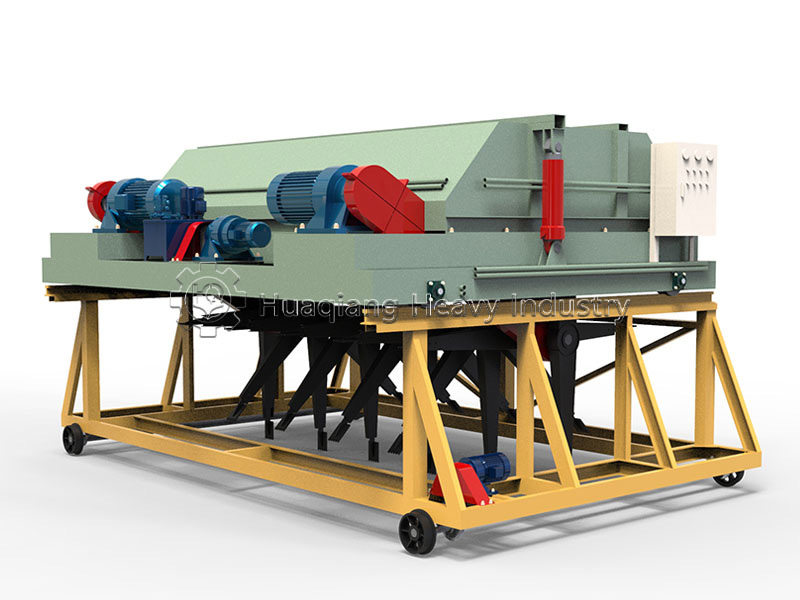

Agricultural crop residues are cost-effective, including corn, wheat, and rice straw, and are rich in cellulose and lignin, improving soil aeration and water retention. Due to their loose texture and lack of viscosity, they need to be processed by a crushing device before being mixed with livestock and poultry manure for fermentation. If necessary, a fertilizer granulator with a binder can be used to improve granule formation.

Industrial organic byproducts, such as distiller’s grains, vinegar residue, and furfural residue, have high nutrient concentrations and contain unique active ingredients that can enrich the nutrients in organic fertilizers. However, their composition is complex, requiring pretreatment to adjust humidity and pH and remove harmful substances before mixing with other raw materials for fermentation to ensure the safety and stability of the finished product.

By rationally combining these three types of raw materials and precisely controlling the fermentation and pretreatment processes with organic fertilizer production equipment, nutrient complementarity can be achieved, significantly improving the quality of organic fertilizers and maximizing their fertilizing value.