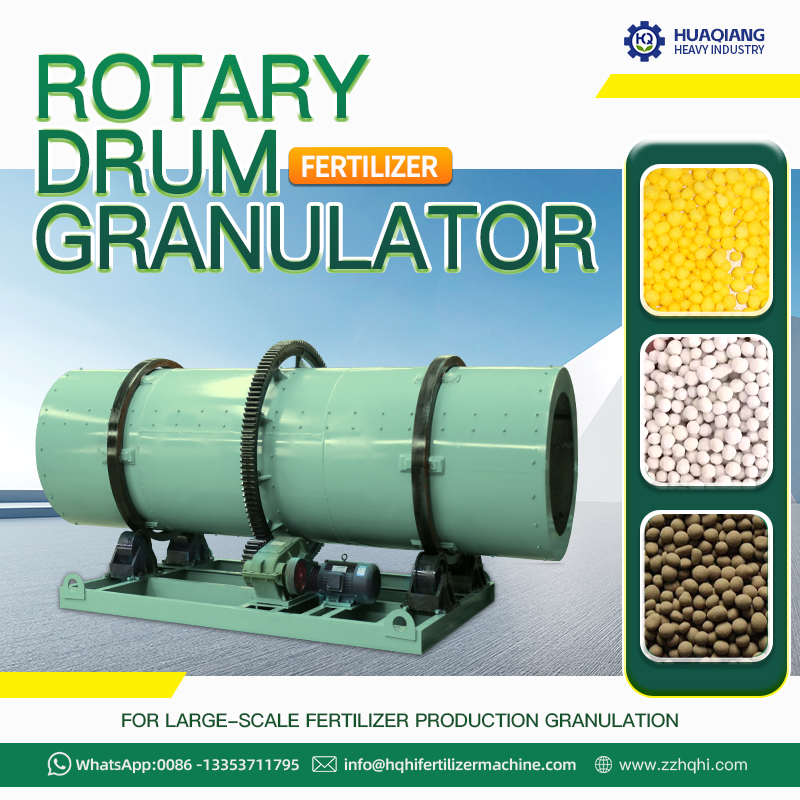

The rotary drum granulator is key equipment in phosphate fertilizer production, suitable for the granulation process of many types. It forms powder into granules through the tumbling action of a rotating drum, offering advantages like high output, good granule formation rates, and strong adaptability.

Phosphate Fertilizers Suitable for Rotary Drum Granulator:

1.Single Superphosphate (SSP)

SSP is a water-soluble phosphate fertilizer containing 14% to 20% available P₂O₅. Because it’s quite acidic, neutralizing agents (like lime or ammonia) need adding during granulation to improve how well the material sticks together. The rotary drum produces uniform SSP granules with good strength for storage and spreading.

2.Triple Superphosphate (TSP)

TSP has much higher P₂O₅content (44% to 52%) than SSP. Granulation requires careful moisture control (usually 8% to 12%) and adding binders (like bentonite or humic acid) to boost the granules’ strength and resistance to wear.

3.Ammonium Phosphate Fertilizers (MAP/DAP)

Monoammonium Phosphate (MAP): Contains 48% to 52% P₂O₅and 10% to 12% N. Granulation needs pH adjustment to prevent the material becoming too sticky, which affects granule formation.

Diammonium Phosphate (DAP): Contains 46% to 48% P₂O₅and 16% to 18% N. The higher nitrogen content means temperature control during granulation is important to prevent nitrogen loss.

4.Organic-Inorganic Compound Phosphate Fertilizers

These are made by granulating phosphate fertilizers (like SSP) mixed with organic materials (like composted manure or humic acid). The rotary drum mixes the materials evenly, creating granules that provide balanced nutrients and improve soil quality.

In summary, the rotary drum granulator is an ideal machine for making phosphate fertilizer granules. By choosing the right process settings, it produces strong, high-quality granules that improve fertilizer effectiveness and make spreading easier.